Txoj kev loj hlob ntawm cov hlau nplaum ruaj khov motors yog ze rau kev tsim cov khoom siv hlau nplaum ruaj khov. Tuam Tshoj yog thawj lub teb chaws nyob rau hauv lub ntiaj teb no nrhiav cov khoom sib nqus ntawm cov khoom siv hlau nplaum ruaj khov thiab siv rau hauv kev xyaum. Ntau tshaj 2,000 xyoo dhau los, Tuam Tshoj tau siv cov khoom sib nqus ntawm cov khoom siv hlau nplaum tas mus li los ua cov khoom sib txuas, uas tau ua lub luag haujlwm loj hauv kev tsav tsheb, kev ua tub rog thiab lwm yam, thiab tau los ua ib qho ntawm plaub qhov kev tsim khoom zoo tshaj plaws ntawm Tuam Tshoj thaum ub.

Thawj lub cev muaj zog hauv ntiaj teb, uas tau tshwm sim hauv xyoo 1920, yog lub tshuab hlau nplaum ruaj khov uas siv cov hlau nplaum ruaj khov los ua kom muaj zog sib nqus. Txawm li cas los xij, cov khoom siv hlau nplaum ruaj khov siv nyob rau lub sijhawm ntawd yog ntuj magnetite (Fe3O4), uas muaj lub zog sib nqus tsawg heev. Lub cev muaj zog ua los ntawm nws yog qhov loj me thiab tau hloov sai sai los ntawm lub tshuab hluav taws xob excitation.

Nrog rau kev loj hlob sai ntawm ntau lub cev muaj zog thiab kev tsim cov hlau nplaum tam sim no, tib neeg tau ua qhov kev tshawb fawb tob txog cov txheej txheem, muaj pes tsawg leeg thiab kev tsim tshuab ntawm cov khoom siv hlau nplaum ruaj khov, thiab tau tshawb pom ntau yam khoom siv hlau nplaum ruaj khov xws li carbon hlau, tungsten steel (qhov siab tshaj plaws sib nqus khoom ntawm li 2.7 kJ / m3), thiab cobalt hlau 7 / m3 (maximum J.

Tshwj xeeb, cov tsos ntawm aluminium nickel cobalt ruaj khov hlau nplaum nyob rau xyoo 1930 (cov khoom siv hluav taws xob sib nqus siab tshaj plaws tuaj yeem ncav cuag 85 kJ / m3) thiab ferrite cov hlau nplaum ruaj khov nyob rau xyoo 1950 (cov khoom siv hluav taws xob ntau tshaj plaws tuaj yeem ncav cuag 40 kJ / m3) tau txhim kho cov khoom sib nqus zoo heev, thiab ntau yam micro thiab cov khoom siv hlau nplaum mus tas li. yog li ntawm ob peb milliwatts mus rau kaum ntawm kilowatts. Lawv tau siv dav hauv kev ua tub rog, kev lag luam thiab kev ua liaj ua teb thiab kev ua neej nyob txhua hnub, thiab lawv cov txiaj ntsig tau nce ntau.

Raws li txoj cai, nyob rau lub sijhawm no, kev ua tiav tau ua tiav hauv kev tsim txoj kev xav, kev suav cov txheej txheem, kev sib nqus thiab kev tsim tshuab ntawm cov hlau nplaum ruaj khov, tsim cov txheej txheem kev tshuaj xyuas thiab kev tshawb fawb uas sawv cev los ntawm cov hlau nplaum ruaj khov ua haujlwm daim duab kos duab. Txawm li cas los xij, lub zog quab yuam ntawm AlNiCo cov hlau nplaum ruaj khov yog qis (36-160 kA / m), thiab qhov sib nqus sib nqus ntawm ferrite ruaj khov hlau nplaum tsis siab (0.2-0.44 T), uas txwv lawv cov ntawv thov ntau yam hauv cov motors.

Nws tsis yog txog thaum xyoo 1960 thiab 1980s uas tsis tshua muaj lub ntiaj teb cobalt cov hlau nplaum ruaj khov thiab neodymium hlau boron cov hlau nplaum ruaj khov (suav hu ua cov hlau nplaum tsis tshua muaj hauv ntiaj teb) tau tawm ib tom qab. Lawv cov khoom sib nqus zoo heev ntawm cov khoom sib nqus zoo sib nqus, siab coercive, cov khoom siv hluav taws xob sib nqus thiab cov kab demagnetization nkhaus yog tshwj xeeb tshaj yog tsim rau kev tsim cov motors, yog li ushering txoj kev loj hlob ntawm cov hlau nplaum ruaj khov motors mus rau lub sijhawm tshiab keeb kwm.

1.Permanent sib nqus cov ntaub ntawv

Cov khoom siv hlau nplaum ruaj khov uas feem ntau siv hauv lub cev muaj xws li cov hlau nplaum sintered thiab cov hlau nplaum sib txuas, cov hom tseem ceeb yog aluminium nickel cobalt, ferrite, samarium cobalt, neodymium hlau boron, thiab lwm yam.

Alnico: Alnico cov khoom siv hlau nplaum ruaj khov yog ib qho ntawm cov khoom siv hlau nplaum ruaj khov, thiab nws cov txheej txheem kev npaj thiab thev naus laus zis kuj paub tab.

Permanent ferrite: Nyob rau xyoo 1950, ferrite pib vam meej, tshwj xeeb tshaj yog nyob rau xyoo 1970, thaum strontium ferrite nrog kev sib raug zoo thiab kev sib nqus zog tau muab tso rau hauv ntau qhov ntau, nthuav dav siv cov ferrite mus tas li. Raws li cov khoom siv hlau nplaum uas tsis yog xim hlau, ferrite tsis muaj qhov tsis zoo ntawm oxidation yooj yim, tsis tshua muaj Curie kub thiab cov nqi siab ntawm cov khoom siv hlau nplaum ruaj khov, yog li nws nrov heev.

Samarium cobalt: Cov khoom siv hlau nplaum ruaj khov nrog cov khoom sib nqus zoo heev uas tau tshwm sim hauv nruab nrab-1960s thiab muaj kev ua haujlwm ruaj khov. Samarium cobalt yog tshwj xeeb tshaj yog haum rau kev tsim motors nyob rau hauv cov nqe lus ntawm magnetic zog, tab sis vim nws cov nqi siab, nws yog tsuas yog siv nyob rau hauv kev tshawb fawb thiab kev loj hlob ntawm cov tub rog motors xws li aviation, aerospace, thiab riam phom, thiab cov motors nyob rau hauv high-tech teb uas muaj kev kawm siab thiab tus nqi tsis yog lub ntsiab tseem ceeb.

NdFeB: NdFeB cov khoom siv hlau nplaum yog cov hlau nplaum ntawm neodymium, hlau oxide, thiab lwm yam, tseem hu ua hlau nplaum. Nws muaj cov khoom siv hluav taws xob sib nqus siab heev thiab lub zog quab yuam. Nyob rau tib lub sijhawm, qhov zoo ntawm lub zog siab ntom ntom ua rau NdFeB cov khoom siv hlau nplaum ruaj khov siv dav hauv kev lag luam niaj hnub thiab cov cuab yeej siv hluav taws xob, ua rau nws tuaj yeem ua rau me me, sib zog thiab nyias cov cuab yeej xws li cov twj paj nruag, electroacoustic motors, sib nqus sib nqus thiab magnetization. Vim nws muaj ntau cov neodymium thiab hlau, nws yooj yim rau xeb. Surface chemical passivation yog ib qho kev daws teeb meem zoo tshaj plaws tam sim no.

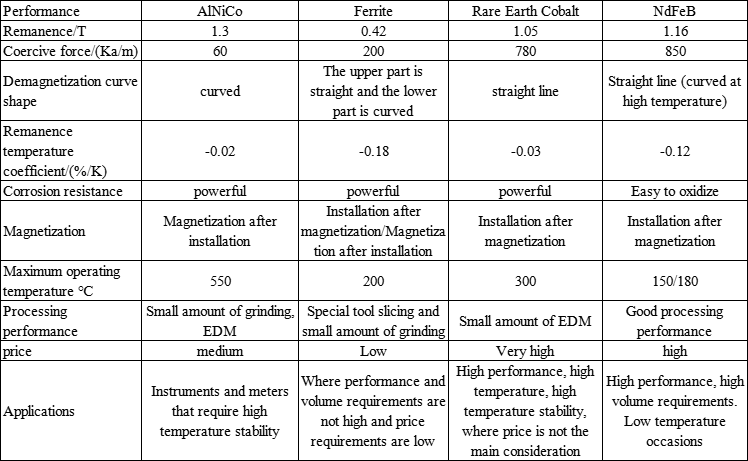

Corrosion kuj, siab tshaj plaws kev khiav hauj lwm kub, kev ua tau zoo, demagnetization nkhaus puab,

thiab tus nqi sib piv ntawm cov khoom siv hlau nplaum uas nquag siv rau cov motors (Daim duab)

2.Kev cuam tshuam ntawm cov hlau nplaum hlau zoo thiab kam rau ua haujlwm ntawm lub cev muaj zog

1. Kev cuam tshuam ntawm cov hlau nplaum hlau tuab

Thaum cov hlau nplaum sab hauv lossis sab nraud raug kho, qhov sib txawv ntawm huab cua txo thiab qhov zoo sib nqus flux nce thaum lub thickness nce. Qhov pom tseeb tshwm sim yog tias tsis muaj qhov nrawm nrawm thiab qhov tsis muaj kev thauj khoom tam sim no txo qis hauv tib qhov seem hlau nplaum, thiab qhov siab tshaj plaws ntawm lub cev muaj zog nce. Txawm li cas los xij, kuj tseem muaj qhov tsis zoo, xws li nce kev sib hloov kev co ntawm lub cev muaj zog thiab ib qho kev ua haujlwm zoo ntawm lub cev muaj zog. Yog li ntawd, lub thickness ntawm lub cev muaj zog hlau nplaum yuav tsum tau raws li zoo raws li qhov ua tau kom txo tau kev co.

2.Influence ntawm magnetic steel dav

Rau qhov sib txuas sib txuas ntawm cov hlau nplaum tsis muaj lub cev muaj zog, tag nrho qhov sib txawv tsis tuaj yeem tshaj 0.5 hli. Yog tias nws me dhau, nws yuav tsis raug ntsia. Yog hais tias nws loj dhau lawm, lub cev muaj zog yuav vibrate thiab txo efficiency. Qhov no yog vim hais tias txoj hauj lwm ntawm Hall lub caij uas ntsuas txoj hauj lwm ntawm cov hlau nplaum tsis sib haum mus rau qhov tseeb txoj hauj lwm ntawm cov hlau nplaum, thiab qhov dav yuav tsum zoo ib yam, txwv tsis pub lub cev muaj zog yuav muaj tsawg efficiency thiab loj kev co.

Rau txhuam cov motors, muaj qee qhov sib txawv ntawm cov hlau nplaum, uas yog tshwj tseg rau thaj tsam kev hloov pauv ntawm cov khoom siv. Txawm hais tias muaj qhov sib txawv, cov tuam ntxhab feem ntau muaj cov txheej txheem kev teeb tsa cov hlau nplaum nruj kom ntseeg tau tias qhov tseeb ntawm qhov kev teeb tsa kom ntseeg tau tias qhov tseeb installation txoj haujlwm ntawm lub cev muaj zog hlau nplaum. Yog tias qhov dav ntawm cov hlau nplaum ntau dhau, nws yuav tsis raug ntsia; Yog tias qhov dav ntawm cov hlau nplaum me me dhau lawm, nws yuav ua rau cov hlau nplaum tsis zoo, lub cev muaj zog yuav vibrate ntau dua, thiab kev ua haujlwm yuav raug txo.

3.Qhov cuam tshuam ntawm magnetic steel chamfer loj thiab tsis-chamfer

Yog tias lub chamfer tsis ua tiav, tus nqi ntawm kev hloov pauv ntawm cov hlau nplaum ntawm ntug ntawm lub cev muaj zog magnetic teb yuav loj, ua rau lub cev muaj zog pulsation. Qhov loj dua lub chamfer, qhov me dua qhov kev vibration. Txawm li cas los xij, chamfering feem ntau ua rau qee qhov poob hauv cov hlau nplaum sib nqus. Rau qee qhov tshwj xeeb, qhov sib nqus flux poob yog 0.5 ~ 1.5% thaum lub chamfer yog 0.8. Rau brushed motors nrog tsawg residual hlau nplaum, tsim nyog txo qhov luaj li cas ntawm chamfer yuav pab them rau cov seem hlau nplaum, tab sis lub cev muaj zog lub pulsation yuav nce. Feem ntau hais lus, thaum cov hlau nplaum seem tsis tshua muaj, qhov kam rau ua qhov ntev ntawm cov kev taw qhia tuaj yeem ua kom haum, uas tuaj yeem ua kom cov hlau nplaum zoo rau qee qhov thiab ua kom lub cev muaj zog qhov kev ua tau zoo tsis hloov pauv.

3.Notes ntawm cov hlau nplaum ruaj khov motors

1. Sib nqus Circuit Court qauv thiab tsim kev suav

Txhawm rau muab kev ua si tag nrho rau cov khoom sib nqus ntawm ntau yam khoom siv hlau nplaum ruaj khov, tshwj xeeb tshaj yog cov khoom sib nqus zoo heev ntawm cov hlau nplaum tsis tshua muaj hauv ntiaj teb, thiab tsim cov khoom siv hlau nplaum ruaj khov, nws tsis tuaj yeem siv cov qauv thiab tsim cov qauv kev suav ntawm cov khoom siv hlau nplaum ib txwm muaj lossis cov khoom siv hluav taws xob. Cov tswv yim tsim qauv tshiab yuav tsum tau tsim kom rov ntsuas dua thiab txhim kho cov qauv sib nqus hluav taws xob. Nrog rau kev txhim kho sai ntawm computer hardware thiab software technology, nrog rau kev txhim kho txuas ntxiv ntawm cov qauv tsim niaj hnub xws li electromagnetic teb cov lej suav, optimization tsim thiab simulation thev naus laus zis, thiab los ntawm kev sib koom ua ke ntawm lub cev muaj zog kev kawm thiab engineering zej zog, kev ua tiav tau ua tiav hauv kev tsim qauv, kev suav cov txheej txheem, cov txheej txheem txheej txheem thiab kev tswj cov thev naus laus zis ntawm kev tsim cov hlau nplaum ruaj khov thiab kev tshawb fawb hauv computer thiab kev tshawb fawb. uas sib txuas cov electromagnetic teb cov lej suav thiab sib npaug sib nqus Circuit Court analytical tov, thiab tab tom txhim kho tsis tu ncua.

2. Irreversible demagnetization teeb meem

Yog tias qhov tsim lossis siv tsis raug, lub tshuab hlau nplaum ruaj khov tuaj yeem tsim qhov tsis tuaj yeem demagnetization, lossis demagnetization, thaum kub siab dhau (NdFeB cov hlau nplaum ruaj khov) lossis qis dhau (ferrite ruaj khov hlau nplaum), nyob rau hauv cov tshuaj tiv thaiv armature los ntawm qhov cuam tshuam tam sim no, lossis hauv qab kev vibration hnyav, uas yuav txo qis kev ua haujlwm ntawm lub cev muaj zog thiab txawm tias ua rau nws siv tsis tau. Yog li ntawd, nws yog ib qho tsim nyog los kawm thiab tsim cov txheej txheem thiab cov cuab yeej tsim nyog rau cov tuam txhab tsim hluav taws xob los xyuas cov thermal stability ntawm cov khoom siv hlau nplaum ruaj khov, thiab txheeb xyuas cov peev txheej los tiv thaiv demagnetization ntawm ntau yam qauv, kom cov kev ntsuas sib xws tuaj yeem raug coj los siv thaum tsim thiab tsim khoom los xyuas kom meej tias cov hlau nplaum ruaj khov tsis ploj.

3.Cov teeb meem nqi

Txij li thaum lub ntiaj teb tsis tshua muaj cov hlau nplaum ruaj khov tseem kim heev, tus nqi ntawm lub ntiaj teb tsis tshua muaj cov hlau nplaum ruaj khov motors feem ntau siab dua li ntawm cov hluav taws xob excitation motors, uas yuav tsum tau them nyiaj los ntawm nws cov kev ua haujlwm siab thiab kev txuag hauv cov nqi khiav lag luam. Qee lub sijhawm, xws li lub suab coil motors rau lub computer disk drives, kev siv NdFeB cov hlau nplaum ruaj khov txhim kho kev ua tau zoo, txo qhov ntim thiab loj, thiab txo cov nqi tag nrho. Thaum tsim qauv, nws yog ib qho tsim nyog yuav tsum tau ua kom muaj kev sib piv ntawm kev ua tau zoo thiab tus nqi raws li kev siv tshwj xeeb thiab cov kev xav tau, thiab tsim kho cov txheej txheem tsim kho thiab txhim kho cov qauv tsim kom txo tau cov nqi.

Anhui Mingteng Permanent Magnet Electromechanical Equipment Co., Ltd.https://www.mingtengmotor.com/). Tus nqi demagnetization ntawm cov hlau nplaum ruaj khov lub cev muaj zog hlau nplaum tsis muaj ntau tshaj ib txhiab ib xyoos.

Cov khoom siv hlau nplaum ruaj khov ntawm cov hlau nplaum tas mus li lub cev muaj zog rotor ntawm peb lub tuam txhab txais cov khoom siv hluav taws xob sib nqus siab thiab siab intrinsic coercivity sintered NdFeB, thiab cov qib sib txawv yog N38SH, N38UH, N40UH, N42UH, thiab lwm yam. Siv N38SH, feem ntau siv qib sib nqus ntawm peb lub tuam txhab khoom siab tshaj plaws 3 8- piv txwv. 38 MGOe; SH sawv cev rau qhov siab tshaj plaws kub tsis kam ntawm 150 ℃. UH muaj qhov kub siab tshaj plaws ntawm 180 ℃. Lub tuam txhab tau tsim cov cuab yeej tshaj lij thiab cov lus qhia cov khoom siv rau cov hlau nplaum sib nqus, thiab soj ntsuam cov polarity ntawm cov hlau nplaum sib nqus nrog qhov tsim nyog, kom cov txheeb ze sib nqus flux tus nqi ntawm txhua qhov sib nqus hlau yog nyob ze, uas ua kom cov symmetry ntawm cov hlau nplaum sib nqus thiab qhov zoo ntawm cov hlau nplaum sib nqus.

Copyright: Kab lus no yog rov luam tawm ntawm WeChat pej xeem naj npawb "hnub no lub cev muaj zog", qhov txuas thawj https://mp.weixin.qq.com/s/zZn3UsYZeDwicEDwIdsbPg

Kab lus no tsis sawv cev rau peb lub tuam txhab txoj kev xav. Yog tias koj muaj kev xav lossis kev xav, thov kho peb!

Post lub sij hawm: Aug-30-2024