Qhov sib txawv ntawm ntau hom motors

1. Qhov sib txawv ntawm DC thiab AC motors

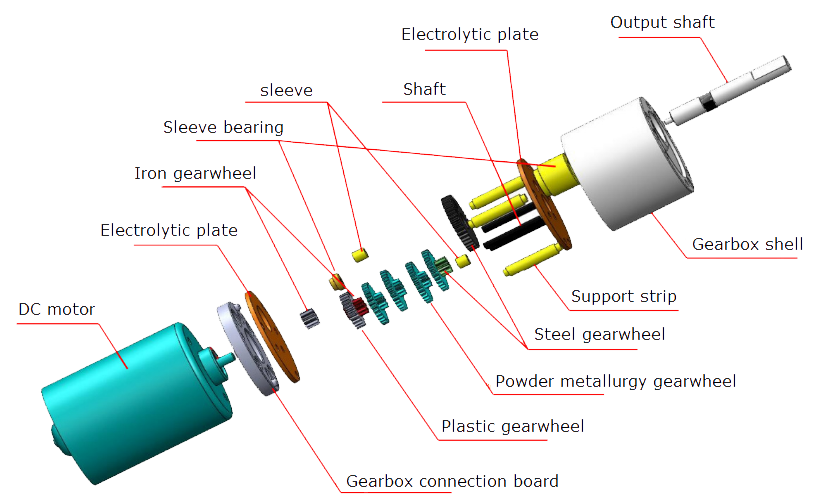

DC motor structure daim duab

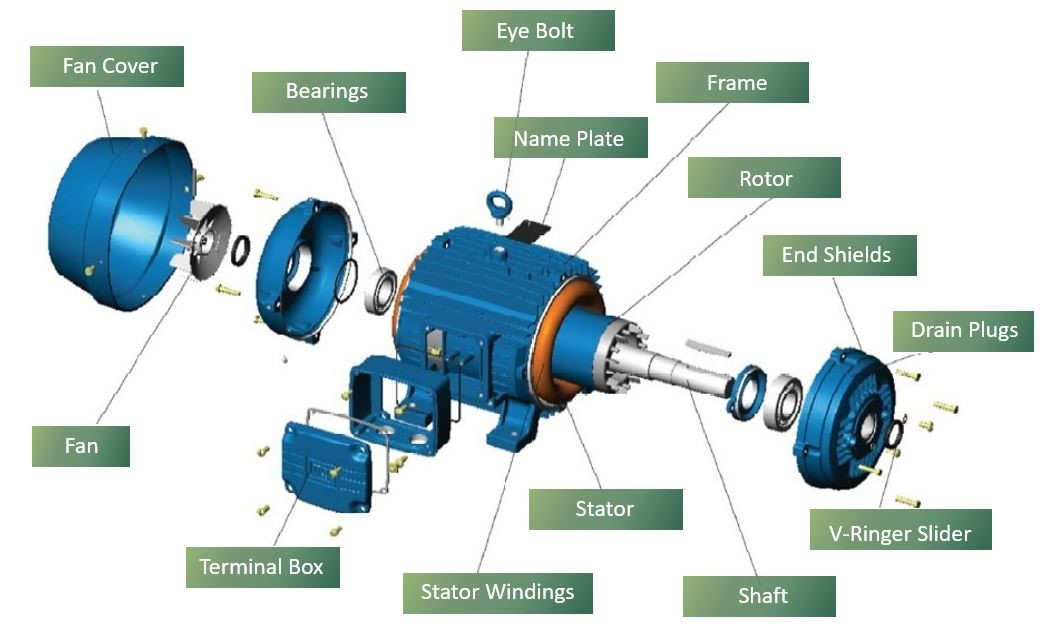

AC motor structure daim duab

DC motors siv tam sim no ncaj qha raws li lawv lub zog, thaum AC motors siv alternating tam sim no raws li lawv lub zog.

Structurely, lub hauv paus ntsiab lus ntawm DC motors yog qhov yooj yim, tab sis cov qauv yog complex thiab tsis yooj yim rau kev tswj. Lub hauv paus ntsiab lus ntawm AC motors yog complex tab sis cov qauv yog kuj yooj yim, thiab nws yog yooj yim los tswj dua DC motors.

Hais txog tus nqi, DC motors nrog tib lub zog yog siab dua AC motors. Nrog rau cov cuab yeej tswj ceev, tus nqi ntawm DC yog siab dua li ntawm AC. Tau kawg, kuj tseem muaj qhov sib txawv ntawm cov qauv thiab kev saib xyuas.

Nyob rau hauv cov nqe lus ntawm kev ua tau zoo, vim hais tias qhov ceev ntawm DC motors yog ruaj khov thiab ceev tswj yog qhov tseeb, uas tsis tuaj yeem ua tiav los ntawm AC motors, DC motors yuav tsum tau siv los hloov AC motors raws li kev ceev ceev.

Kev tswj ceev ntawm AC motors yog qhov nyuaj, tab sis nws tau siv dav vim tias cov nroj tsuag tshuaj siv AC zog.

2. Qhov sib txawv ntawm synchronous thiab asynchronous motors

Yog hais tias lub rotor tig ntawm tib lub ceev raws li lub stator, nws yog hu ua synchronous lub cev muaj zog. Yog tias lawv tsis zoo ib yam, nws yog hu ua asynchronous motor.

3. Qhov sib txawv ntawm qhov sib txawv ntawm qhov sib txawv thiab qhov sib txawv zaus

Ua ntej tshaj plaws, cov motors zoo tib yam tsis tuaj yeem siv los ua cov motors sib txawv. Ordinary motors yog tsim los raws li qhov zaus thiab qhov tsis tu ncua, thiab nws tsis tuaj yeem hloov kho kom haum raws li qhov yuav tsum tau muaj ntawm kev hloov pauv ceev, yog li lawv tsis tuaj yeem siv los ua cov motors sib txawv.

Qhov cuam tshuam ntawm zaus converters ntawm lub cev muaj zog yog nyob ntawm qhov ua tau zoo thiab qhov kub thiab txias ntawm cov motors.

Lub tshuab hloov zaus tuaj yeem tsim cov qib sib txawv ntawm qhov sib txawv ntawm qhov sib haum xeeb thiab qhov tam sim no thaum lub sijhawm ua haujlwm, kom lub cev muaj zog khiav hauv qhov tsis yog-sinusoidal voltage thiab tam sim no. Qhov kev txiav txim siab siab nyob rau hauv nws yuav ua rau lub cev muaj zog stator tooj liab poob, rotor tooj liab poob, hlau poob thiab ntxiv poob kom nce.

Qhov tseem ceeb tshaj plaws ntawm cov no yog rotor tooj liab poob. Cov kev poob no yuav ua rau lub cev muaj zog ua kom muaj cua sov ntxiv, txo kev ua haujlwm, txo cov zis hluav taws xob, thiab qhov kub thiab txias ntawm cov motors zoo ib yam yuav nce 10% -20%.

Cov zaus hloov pauv cov cab kuj zaus nyob ntawm ntau kilohertz mus rau ntau tshaj kaum kilohertz, uas ua rau lub stator winding ntawm lub cev muaj zog tiv taus lub zog siab heev, uas yog sib npaug rau kev siv lub zog siab heev rau lub cev muaj zog, ua rau kev sib tshuam ntawm lub cev muaj zog tiv taus qhov kev sim siab dua.

Thaum cov motors zoo tib yam tau siv los ntawm cov zaus hloov pauv, kev co thiab suab nrov los ntawm electromagnetic, mechanical, cua thiab lwm yam yuav ua rau nyuaj.

Cov harmonics uas muaj nyob rau hauv lub variable zaus fais fab mov cuam tshuam nrog inherent spatial harmonics ntawm lub electromagnetic ib feem ntawm lub cev muaj zog, tsim ntau yam electromagnetic excitation rog, yog li ua rau lub suab nrov.

Vim muaj kev khiav hauj lwm ntau zaus ntawm lub cev muaj zog thiab qhov sib txawv ntawm qhov sib txawv loj, qhov zaus ntawm ntau yam hluav taws xob hluav taws xob tsis zoo yog qhov nyuaj kom tsis txhob muaj qhov sib txawv ntawm qhov sib txawv ntawm ntau yam qauv ntawm lub cev muaj zog.

Thaum lub hwj chim mov zaus tsawg, qhov poob tshwm sim los ntawm kev txiav txim siab sib haum xeeb hauv lub hwj chim mov yog loj; Thib ob, thaum lub zog ntawm lub zog hloov pauv tau txo qis, cov cua txias ntim txo qis hauv qhov sib piv ncaj qha mus rau lub voos xwmfab ntawm qhov nrawm, ua rau cov cua sov ntawm lub cev tsis tau dissipated, qhov kub thiab txias nce sharply, thiab nws yog ib qho nyuaj rau ua tiav qhov tso zis torque tas li.

4. Cov qauv sib txawv ntawm cov motors zoo tib yam thiab lub cev muaj zog sib txawv

01. Cov txheej txheem rwb thaiv tsev siab dua

Feem ntau, qhov rwb thaiv tsev theem ntawm qhov sib txawv zaus motors yog F lossis siab dua. Lub rwb thaiv tsev rau hauv av thiab rwb thaiv tsev lub zog ntawm cov hlau tig yuav tsum tau ntxiv dag zog, thiab lub peev xwm ntawm cov rwb thaiv tsev tiv thaiv impulse voltage yuav tsum tau txiav txim siab tshwj xeeb.

02. Kev co siab dua thiab cov suab nrov uas yuav tsum tau ua rau lub cev muaj zog sib txawv

Kev sib txawv zaus motors yuav tsum xav txog tag nrho cov rigidity ntawm lub cev muaj zog Cheebtsam thiab tag nrho, thiab sim ua kom lawv lub ntuj zaus kom tsis txhob resonance nrog txhua lub zog nthwv dej.

03. Cov txheej txheem txias sib txawv rau lub cev muaj zog sib txawv

Lub cev muaj zog tsis sib xws feem ntau siv qhov cua txias, uas yog, lub ntsiab lub cev muaj zog txias kiv cua yog tsav los ntawm lub cev muaj zog.

04. Yuav tsum muaj kev tiv thaiv sib txawv

Kev ntsuas hluav taws xob rwb thaiv tsev yuav tsum tau txais kev pom zoo rau lub cev muaj zog uas muaj peev xwm ntau dua 160KW. Nws yog tsuas yog yooj yim los tsim magnetic circuit asymmetry thiab ncej tam sim no. Thaum cov khoom tam sim no tsim los ntawm lwm cov khoom siv high-frequency sib xyaw ua ke, cov ncej tam sim no yuav nce siab heev, ua rau muaj kev puas tsuaj, yog li kev ntsuas hluav taws xob feem ntau siv. Rau qhov tsis tu ncua lub zog hloov pauv zaus lub cev muaj zog, thaum qhov ceev tshaj 3000 / min, tshwj xeeb kub-resistant roj yuav tsum tau siv los them rau qhov kub nce ntawm cov kabmob.

05. Cov cua txias sib txawv

Qhov sib txawv zaus lub cev muaj zog cua txias kiv cua siv lub zog ywj pheej los xyuas kom muaj peev xwm ua kom txias tsis tu ncua.

2.Basic paub txog motors

Kev xaiv lub cev muaj zog

Cov ntsiab lus tseem ceeb uas xav tau rau kev xaiv lub cev muaj zog yog:

Hom kev tsav tsheb, ntsuas lub zog, ntsuas hluav taws xob, ntsuas nrawm, thiab lwm yam.

Load type · DC motor · Asynchronous motor · Synchronous motor

Rau cov khoom siv tas mus li nrog cov khoom ruaj khov thiab tsis muaj qhov tshwj xeeb rau kev pib thiab nres, cov hlau nplaum ruaj khov synchronous motors lossis cov squirrel tawb asynchronous motors yuav tsum nyiam, uas yog siv dav hauv tshuab, twj tso kua mis, kiv cua, thiab lwm yam.

Rau kev tsim cov tshuab nrog nquag pib thiab nres thiab xav tau kev pib loj thiab nres lub zog, xws li choj cranes, mine hoists, cua compressors, irreversible dov mills, thiab lwm yam, yuav tsum tau siv cov hlau nplaum ruaj khov synchronous motors lossis lub qhov txhab asynchronous motors.

Rau lub sijhawm tsis muaj kev tswj hwm ceev, qhov yuav tsum tau ua kom ceev nrawm lossis lub zog yuav tsum tau ua kom zoo dua qub, cov hlau nplaum ruaj khov synchronous motors yuav tsum tau siv, xws li cov twj nruab nrab thiab loj dej twj, cua compressors, hoists, mills, thiab lwm yam.

Rau cov tshuab tsim khoom uas yuav tsum tau muaj kev tswj hwm ntau dua 1: 3 thiab xav tau kev tswj xyuas tas li, ruaj khov thiab du, nws raug nquahu kom siv cov hlau nplaum ruaj khov synchronous motors lossis cais DC motors lossis squirrel tawb asynchronous motors nrog kev sib txawv ntawm kev ceev ceev, xws li cov cuab yeej siv tshuab loj, gantrymills, dov, thiab lwm yam.

Feem ntau hais lus, lub cev muaj zog tuaj yeem txiav txim siab los ntawm kev muab hom kev tsav tsheb, ntsuas lub zog, ntsuas hluav taws xob, thiab ntsuas ceev ntawm lub cev muaj zog.

Txawm li cas los xij, yog tias cov kev xav tau ntawm kev thauj khoom yuav tsum tau ua kom zoo, cov kev ntsuas no tseem nyob deb ntawm qhov txaus.

Lwm yam uas yuav tsum tau muab muaj xws li: zaus, ua hauj lwm system, overload yuav tsum, rwb thaiv tsev theem, tiv thaiv theem, lub sij hawm ntawm inertia, load kuj torque nkhaus, installation txoj kev, ambient kub, qhov siab, sab nraum zoov, thiab lwm yam (muab raws li tej yam kev mob)

3.Basic paub txog motors

Cov kauj ruam rau kev xaiv lub cev muaj zog

Thaum lub cev muaj zog khiav lossis tsis ua haujlwm, plaub txoj hauv kev saib, mloog, hnov tsw thiab kov tuaj yeem siv los tiv thaiv thiab tshem tawm qhov ua txhaum ntawm lub sijhawm kom ntseeg tau tias lub cev muaj kev nyab xeeb.

1. Saib

Saib xyuas seb puas muaj qhov txawv txav thaum lub sijhawm ua haujlwm ntawm lub cev muaj zog, uas feem ntau tshwm sim hauv cov xwm txheej hauv qab no.

1. Thaum lub stator winding yog luv luv, koj yuav pom cov pa taws tawm ntawm lub cev muaj zog.

2. Thaum lub cev muaj zog hnyav dhau los yog khiav hauv theem poob, qhov ceev yuav qeeb thiab yuav muaj lub suab "buzzing" hnyav dua.

3. Thaum lub cev muaj zog khiav ib txwm, tab sis dheev nres, koj yuav pom sparks tawm ntawm qhov kev sib txuas xoob; lub fuse yog tshuab los yog ib feem yog daig.

4. Yog hais tias lub cev muaj zog vibrates hnyav, tej zaum yuav yog hais tias cov kis tau tus mob ntaus ntawv yog daig los yog lub cev muaj zog tsis kho zoo, cov ko taw bolts yog xoob, thiab lwm yam.

5. Yog tias muaj cov xim tsis zoo, hlawv cov cim thiab cov pa luam yeeb ntawm cov ntsiab lus sib txuas thiab kev sib txuas hauv lub cev muaj zog, nws txhais tau tias tej zaum yuav muaj cua sov hauv zos, kev sib cuag tsis zoo ntawm tus neeg xyuas pib sib txuas lossis winding burnt, thiab lwm yam.

2. Mloog

Thaum lub cev muaj zog ua haujlwm ib txwm, nws yuav tsum tawm lub suab sib xws thiab sib zog "buzzing" suab, tsis muaj suab nrov thiab suab tshwj xeeb.

Yog hais tias lub suab nrov heev, nrog rau cov suab nrov electromagnetic, lub suab nrov, lub suab nrov nrov, suab nrov ntawm kev sib txhuam, thiab lwm yam, nws yuav yog qhov ua ntej lossis qhov tshwm sim txhaum.

1. Rau lub suab nrov electromagnetic, yog tias lub cev muaj zog ua suab nrov, qis thiab hnyav, cov laj thawj yuav ua raws li hauv qab no:

(1) Qhov sib txawv ntawm huab cua ntawm lub stator thiab lub rotor tsis sib xws. Lub sijhawm no, lub suab nrov thiab qis, thiab lub sijhawm nruab nrab ntawm lub suab nrov thiab qis tseem tsis hloov pauv. Qhov no yog tshwm sim los ntawm kev coj tus cwj pwm coj, uas ua rau lub stator thiab rotor tsis-concentric.

(2) Peb theem tam sim no tsis sib npaug. Qhov no yog tshwm sim los ntawm peb-theem winding yog grounded incorrectly, luv-circuited los yog muaj kev sib cuag tsis zoo. Yog hais tias lub suab yog dull, nws txhais tau hais tias lub cev muaj zog heev overloaded los yog khiav nyob rau hauv ib tug theem-tsis zoo li.

(3) Cov tub ntxhais hlau yog xoob. Thaum lub sijhawm ua haujlwm ntawm lub cev muaj zog, qhov kev vibration ua rau cov tub ntxhais hlau txhim kho bolts kom loosen, ua rau cov hlau core silicon steel ntawv kom loosen thiab ua suab nrov.

2. Rau cov kabmob suab nrov, koj yuav tsum saib xyuas nws nquag thaum lub sijhawm ua haujlwm ntawm lub cev muaj zog. Txoj kev saib xyuas yog: muab ib qho kawg ntawm cov ntsia hlau tiv thaiv qhov kev teeb tsa ntawm cov kabmob thiab lwm qhov kawg ze rau koj lub pob ntseg, thiab koj tuaj yeem hnov lub suab ntawm cov kabmob khiav. Yog tias cov kabmob ua haujlwm ib txwm, lub suab yog lub suab txuas ntxiv thiab zoo "rustling", tsis muaj qhov hloov pauv lossis cov suab sib txhuam hlau.

Yog tias cov suab hauv qab no tshwm sim, nws yog qhov tshwm sim txawv txav:

(1) Muaj lub suab "squeaking" thaum lub bearing khiav. Qhov no yog lub suab sib txhuam hlau, uas feem ntau tshwm sim los ntawm qhov tsis muaj roj hauv cov kabmob. Lub bearing yuav tsum tau disassembled thiab ib tug tsim nyog cov roj yuav tsum tau ntxiv.

(2) Yog tias lub suab "chirping" tshwm sim, qhov no yog lub suab ua thaum lub pob tig. Nws feem ntau tshwm sim los ntawm kev ziab ntawm cov roj lossis tsis muaj roj. Ntxiv cov roj uas tsim nyog tuaj yeem ntxiv.

(3) Yog tias lub suab "nias" lossis "squeaking" tshwm sim, nws yog lub suab tsim los ntawm qhov tsis sib xws ntawm lub pob hauv cov kabmob. Qhov no yog tshwm sim los ntawm kev puas tsuaj ntawm lub pob hauv cov kabmob lossis lub sijhawm ntev tsis siv lub cev muaj zog, ua rau kom qhuav ntawm cov roj.

3. Yog hais tias lub tshuab kis tau tus mob thiab lub tshuab tsav tsheb ua lub suab tsis tu ncua hloov lub suab hloov pauv, nws tuaj yeem ua raws li cov xwm txheej hauv qab no.

(1) Lub sij hawm "pop" suab yog tshwm sim los ntawm txoj siv tsis sib xws.

(2) Lub sijhawm "dong dong" lub suab yog tshwm sim los ntawm kev xoob ntawm qhov sib txuas lossis rub thiab lub ncej, nrog rau hnav ntawm tus yuam sij lossis qhov tseem ceeb.

(3) Lub suab sib tsoo tsis sib xws yog tshwm sim los ntawm cov hniav sib tsoo nrog lub hau kiv cua.

3. tsw

Kev ua tsis tiav kuj tuaj yeem txiav txim siab thiab tiv thaiv los ntawm kev hnov tsw lub cev muaj zog.

Qhib lub thawv sib txuas thiab hnov nws kom pom tias muaj ntxhiab tsw. Yog tias pom muaj xim tshwj xeeb tsis hnov tsw, nws txhais tau hais tias qhov kub thiab txias ntawm lub cev muaj zog heev; Yog tias pom muaj ntxhiab tsw ntxhiab tsw zoo lossis tsis hnov tsw, nws yuav yog tias cov txheej txheem rwb thaiv tsev tu lub net puas lawm los yog cov winding tau raug hlawv.

Yog tias tsis muaj ntxhiab tsw, nws yog qhov yuav tsum tau siv megohmmeter los ntsuas qhov rwb thaiv tsev ntawm qhov cua thiab lub casing. Yog tias nws tsawg dua 0.5 megohms, nws yuav tsum tau qhuav. Yog tias qhov tsis kam yog xoom, nws txhais tau tias nws puas.

4. Kov

Kov qhov kub ntawm qee qhov ntawm lub cev muaj zog tuaj yeem txiav txim siab qhov ua txhaum.

Txhawm rau kom muaj kev nyab xeeb, siv lub nraub qaum ntawm koj txhais tes los kov lub cev lub cev thiab qhov chaw nyob ib puag ncig ntawm cov kabmob.

Yog tias qhov kub tsis txawv txav, cov laj thawj yuav ua tau raws li hauv qab no:

1. Qhov cua tsis zoo. Xws li kiv cua ntog tawm, qhov cua duct blockage, thiab lwm yam.

2. Tshaj dhau. Qhov tam sim no loj heev thiab stator winding yog overheated.

3. Lub stator winding lem yog luv luv lossis peb-theem tam sim no tsis sib npaug.

4. nquag pib lossis nres.

5. Yog hais tias qhov kub thiab txias nyob ib ncig ntawm lub bearings siab dhau lawm, nws yuav tshwm sim los ntawm bearing puas los yog tsis muaj roj.

Lub cev muaj zog bearing kub tswj, ua rau thiab kho qhov txawv txav

Cov kev cai tau teev tseg tias qhov siab tshaj plaws ntawm cov kabmob dov yuav tsum tsis pub tshaj 95 ℃, thiab qhov siab tshaj plaws ntawm cov kabmob zawv zawg yuav tsum tsis pub tshaj 80 ℃. Thiab qhov kub nce siab yuav tsum tsis pub tshaj 55 ℃ (qhov kub thiab txias yog qhov ntsuas kub ntawm qhov kub ntawm qhov ntsuas kub thaum lub sijhawm kuaj).

Ua rau thiab kev kho mob rau qhov kub thiab txias ntau dhau:

(1) Ua rau: Cov ncej yog khoov thiab cov kab nruab nrab tsis raug. Kev Kho Mob: Nrhiav qhov chaw dua.

(2) Ua rau: Lub hauv paus screws yog xoob. Kev kho mob: Tighten lub hauv paus screws.

(3) Ua rau: Lub roj nplua nyeem tsis huv. Kev kho mob: Hloov cov roj nplua nyeem.

(4) Ua rau: Cov roj nplua nyeem tau siv ntev dhau lawm thiab tsis tau hloov. Kev Kho Mob: Ntxuav cov bearings thiab hloov cov roj nplua nyeem.

(5) Ua rau: Lub pob lossis cov menyuam hauv cov kabmob puas lawm. Kev Kho Mob: Hloov cov kabmob nrog ib qho tshiab.

Anhui Mingteng Permanent-Magnetic Machinery & Hluav Taws Xob Khoom Co., Ltd.(https://www.mingtengmotor.com/) tau ntsib 17 xyoo ntawm kev loj hlob sai. Lub tuam txhab tau tsim thiab tsim ntau tshaj 2,000 lub tshuab hlau nplaum ruaj khov nyob rau hauv cov pa, sib txawv zaus, tawg-pov thawj, sib txawv zaus tawg-pov thawj, tsav ncaj qha, thiab tawg-pov thawj ncaj tsav series. Cov motors tau ua tiav ntawm cov kiv cua, dej twj, siv conveyors, pob zeb, mixers, crushers, scrapers, roj twj, spinning machines thiab lwm yam loads nyob rau hauv txawv teb xws li mining, steel, thiab hluav taws xob, ua tau zoo zog-txuag cov teebmeem thiab tau txais kev qhuas dav.

Copyright: Kab lus no yog rov luam tawm ntawm thawj qhov txuas:

https://mp.weixin.qq.com/s/hLDTgGlnZDcGe2Jm1oX0Hg

Kab lus no tsis sawv cev rau peb lub tuam txhab txoj kev xav. Yog tias koj muaj kev xav lossis kev xav, thov kho peb!

Post lub sij hawm: Nov-01-2024