Piv nrog asynchronous motors, cov hlau nplaum ruaj khov synchronous motors muaj qhov zoo ntawm lub zog muaj zog, kev ua haujlwm siab, ntsuas rotor tsis, huab cua loj ntawm stator thiab rotor, kev tswj tau zoo, me me, lub teeb yuag, qauv yooj yim, siab torque / inertia piv, thiab lwm yam. thiab lwm yam, thiab tab tom txhim kho rau siab zog (siab ceev, siab torque), siab functionality thiab miniaturization.

Cov hlau nplaum tas mus li synchronous motors yog tsim los ntawm stators thiab rotors. Lub stator yog tib yam li asynchronous motors, muaj peb-theem windings thiab stator cores. Pre-magnetized (magnetized) cov hlau nplaum ruaj khov yog ntsia rau ntawm lub rotor, thiab ib qho chaw sib nqus tuaj yeem tsim nyob rau hauv qhov chaw ib puag ncig yam tsis muaj lub zog sab nraud, uas ua kom yooj yim rau lub cev muaj zog thiab txuag lub zog. Kab lus no piav qhia txog cov txiaj ntsig zoo ntawm kev txhawb nqa cov hlau nplaum ruaj khov synchronous motors raws li cov yam ntxwv ntawm cov hlau nplaum ruaj khov synchronous motors.

1. Cov txiaj ntsig zoo ntawm cov hlau nplaum ruaj khov synchronous lub cev muaj zog

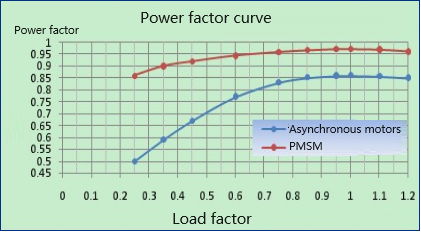

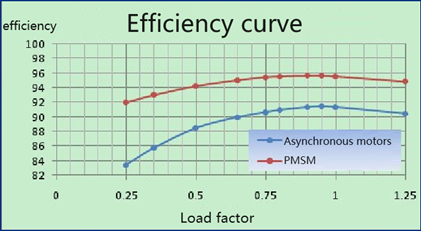

(1) Vim tias lub rotor yog ua los ntawm cov hlau nplaum tas mus li, lub sib nqus flux ntom heev yog qhov siab tam sim no, thiab kev ua kom zoo siab yog tshem tawm. Piv nrog rau asynchronous motors, lub excitation tam sim no ntawm lub stator winding thiab tooj liab thiab hlau poob ntawm lub rotor yog txo, thiab cov reactive tam sim no txo heev. Txij li thaum lub stator thiab rotor sib nqus muaj peev xwm ua tau zoo sib xws, cov tub ntxhais rotor tsis muaj qhov tseem ceeb yoj hlau poob, yog li qhov ua tau zoo (txog rau lub zog muaj zog) thiab lub zog muaj zog (txog rau lub zog reactive) siab dua li cov asynchronous motors. Cov hlau nplaum ruaj khov synchronous motors feem ntau yog tsim los kom muaj lub zog loj thiab ua haujlwm tau zoo txawm tias khiav hauv lub teeb.

Thaum lub load tus nqi ntawm cov asynchronous zoo tib yam motors tsawg dua 50%, lawv cov kev khiav hauj lwm efficiency thiab lub hwj chim factor poob ho. Thaum lub load tus nqi ntawm Mingteng mus tas li hlau nplaum synchronous motors yog 25% -120%, lawv kev khiav hauj lwm efficiency thiab lub hwj chim yam tsis hloov ntau, thiab kev khiav hauj lwm efficiency yog> 90%, thiab lub hwj chim yam yog> 0.85. Lub zog-txuag nyhuv yog qhov tseem ceeb nyob rau hauv lub teeb load, sib txawv load thiab tag nrho load.

(2) Cov hlau nplaum ruaj khov synchronous lub cev muaj zog muaj zog cov khoom siv kho tshuab thiab tiv taus ntau dua rau lub cev muaj zog torque cuam tshuam los ntawm kev hloov pauv. Lub rotor tub ntxhais ntawm ib qho chaw ruaj khov hlau nplaum synchronous lub cev muaj zog tuaj yeem ua rau hauv cov qauv hollow kom txo tau lub rotor inertia, thiab lub sijhawm pib thiab braking yog nrawm dua li ntawm lub tshuab asynchronous. Lub siab torque / inertia piv ua rau cov hlau nplaum ruaj khov synchronous motors tsim nyog rau kev ua haujlwm nyob rau hauv cov lus teb ceev tshaj li asynchronous motors.

(3) Qhov loj ntawm cov hlau nplaum ruaj khov synchronous motors yog me dua li ntawm asynchronous motors, thiab lawv qhov hnyav kuj tseem sib dua. Nrog tib lub tshav kub dissipation thiab cov ntaub ntawv rwb thaiv tsev, lub zog ceev ntawm cov hlau nplaum ruaj khov synchronous motors yog ntau tshaj ob zaug ntawm peb-theem asynchronous motors.

(4) Cov qauv rotor yog qhov yooj yim heev, uas yooj yim los tswj thiab txhim kho kev ruaj ntseg ntawm kev ua haujlwm.

Txij li peb-theem asynchronous motors yuav tsum tau tsim nrog lub zog ntau dua, qhov sib txawv ntawm lub stator thiab rotor yuav tsum tau ua kom me me. Nyob rau tib lub sijhawm, qhov sib txawv ntawm qhov sib txawv ntawm huab cua kuj tseem ceeb heev rau kev ua haujlwm nyab xeeb thiab kev co suab nrov ntawm lub cev muaj zog. Yog li ntawd, qhov yuav tsum tau ntawm cov duab thiab txoj hauj lwm kam rau ua thiab sib dhos concentricity ntawm lub asynchronous lub cev muaj zog kuj nruj, thiab txoj kev ywj pheej ntawm cov bearing clearance xaiv yog me me. Asynchronous motors nrog lub hauv paus loj dua feem ntau siv cov roj da dej lubrication bearings, uas yuav tsum tau ntim cov roj lubricating hauv lub sijhawm ua haujlwm. Roj to los yog untimely filling ntawm cov roj kab noj hniav yuav ua rau kom qhov tsis ua hauj lwm ntawm cov kabmob. Nyob rau hauv kev saib xyuas ntawm peb-theem asynchronous motors, kev saib xyuas ntawm bearings account rau ib tug loj feem. Tsis tas li ntawd, vim muaj qhov cuam tshuam tam sim no nyob rau hauv lub rotor ntawm peb-theem asynchronous lub cev muaj zog, qhov teeb meem ntawm hluav taws xob corrosion ntawm cov kabmob kuj tau txhawj xeeb los ntawm ntau tus kws tshawb fawb hauv xyoo tas los no.

Cov hlau nplaum tas mus li synchronous motors tsis muaj teeb meem zoo li no. Vim qhov loj ntawm huab cua sib txawv ntawm cov hlau nplaum ruaj khov synchronous lub cev muaj zog, cov teeb meem saum toj no tshwm sim los ntawm qhov sib txawv me me ntawm lub tshuab asynchronous tsis pom tseeb hauv lub tshuab synchronous. Nyob rau tib lub sijhawm, cov kabmob ntawm cov hlau nplaum ruaj khov synchronous lub cev muaj zog siv roj-lubricated bearings nrog plua plav npog. Cov kabmob tau raug kaw nrog qhov tsim nyog ntawm cov roj zoo thaum tawm hauv lub hoobkas. Kev pabcuam lub neej ntawm cov hlau nplaum ruaj khov synchronous lub cev muaj zog yog ntau dua li ntawm asynchronous lub cev muaj zog.

Txhawm rau tiv thaiv cov ncej tam sim no los ntawm corroding cov kabmob, Anhui Mingteng mus tas li hlau nplaum lub cev muaj zog txais kev tsim cov rwb thaiv tsev rau cov kabmob sib dhos ntawm tus Tsov tus tw kawg, uas tuaj yeem ua tiav cov nyhuv ntawm insulating cov kabmob, thiab tus nqi qis dua li ntawm insulating cov kabmob. Txhawm rau kom ntseeg tau tias lub neej ua haujlwm ib txwm muaj ntawm lub cev muaj zog, lub rotor ib feem ntawm tag nrho cov hlau nplaum ruaj khov synchronous direct tsav motors ntawm Anhui Mingteng muaj cov qauv kev txhawb nqa tshwj xeeb, thiab qhov chaw hloov ntawm cov kabmob yog tib yam li asynchronous motors. Tom qab kev hloov pauv thiab kev saib xyuas tuaj yeem txuag tau cov nqi thauj khoom, txuag lub sijhawm txij nkawm, thiab zoo dua lav tus neeg siv khoom kev ntseeg siab.

2. Cov ntawv thov ntawm cov hlau nplaum ruaj khov synchronous motors hloov asynchronous motors

2.1 Qhov sib txawv zaus ceev txoj cai high-voltage ultra-high-efficiency peb-theem ruaj khov hlau nplaum synchronous lub cev muaj zog rau ntsug zeb hauv kev lag luam cement

Siv lub ultra-high-efficiency mus tas li hlau nplaum synchronous lub cev muaj zog TYPKK1000-6 5300kW 10kV hloov asynchronous motor transformation ua piv txwv. Cov khoom no yog thawj domestic high-voltage ruaj khov hlau nplaum lub cev muaj zog tshaj 5MW rau ntsug zeb transformation muab los ntawm Anhui Mingteng rau lub tuam txhab cov ntaub ntawv nyob rau hauv 2021. Piv nrog rau cov thawj asynchronous lub cev muaj zog system, lub zog txuag tus nqi nce mus txog 8%, thiab ntau lawm nce mus txog 10%. Qhov nruab nrab load tus nqi yog 80%, qhov ua tau zoo ntawm cov hlau nplaum ruaj khov yog 97.9%, thiab cov nqi txuag hluav taws xob txhua xyoo yog: (18.7097 lab yuan ÷ 0.92) × 8% = 1.6269 lab yuan; tus nqi txuag hluav taws xob hauv 15 xyoo yog: (18.7097 lab yuan ÷ 0.92) × 8% × 15 xyoo = 24.4040 lab yuan; Cov peev nyiaj hloov pauv tau rov qab los hauv 15 lub hlis, thiab cov nyiaj rov qab los ntawm kev nqis peev tau txais rau 14 xyoo sib law liag.

Anhui Mingteng muab tag nrho cov ntsug zeb hloov khoom siv rau lub tuam txhab khoom siv hauv Shandong (TYPKK1000-6 5300kW 10kV)

2.2 Tsawg-voltage self-pib ultra-high-efficiency peb-theem mus tas li hlau nplaum synchronous lub cev muaj zog rau kev lag luam tshuaj tov khoom

Siv lub ultra-high-efficiency mus tas li hlau nplaum synchronous lub cev muaj zog TYCX315L1-4 160kW 380V hloov asynchronous motor transformation ua piv txwv. Cov khoom no tau muab los ntawm Anhui Mingteng hauv 2015 rau kev hloov pauv ntawm cov khoom sib tov thiab crusher motors hauv kev lag luam tshuaj. TYCX315L1-4 160kW 380V yog tsim rau kev sib tov ua haujlwm. Los ntawm kev xam lub zog noj ib tuj ib lub sij hawm, tus neeg siv tau xam tias 160kw ruaj khov hlau nplaum synchronous lub cev muaj zog txuag 11.5% hluav taws xob ntau dua li qub asynchronous lub cev muaj zog nrog tib lub zog. Tom qab cuaj xyoo ntawm kev siv tiag tiag, cov neeg siv txaus siab rau lub zog txuag tus nqi, kub nce, suab nrov, tam sim no thiab lwm yam ntsuas ntawm Mingteng ruaj khov hlau nplaum synchronous lub cev muaj zog hauv kev ua haujlwm tiag tiag.

Anhui Mingteng muab kev hloov pauv hloov pauv rau lub tuam txhab tshuaj hauv Guizhou (TYCX315L1-4 160kW 380V)

3. Cov teeb meem uas cov neeg siv saib xyuas

3.1 Lub neej tsav Lub neej ntawm tag nrho lub cev muaj zog nyob ntawm lub neej ntawm cov kabmob. Lub tsev nyob hauv lub cev tau txais kev tiv thaiv qib IP54, uas tuaj yeem nce mus rau IP65 nyob rau hauv cov xwm txheej tshwj xeeb, ua tau raws li qhov yuav tsum tau siv ntawm feem ntau cov plua plav thiab ntub dej. Nyob rau hauv cov xwm txheej ntawm kev ua kom zoo coaxiality ntawm lub cev muaj zog ncej txuas ntxiv thiab tsim nyog radial load ntawm ncej, qhov tsawg kawg nkaus kev pab cuam lub neej ntawm lub cev muaj zog bearing yog ntau tshaj 20,000 teev. Qhov thib ob yog lub neej ntawm cov kiv cua txias, uas yog ntev dua li ntawm lub tshuab ua haujlwm capacitor. Thaum khiav mus ntev hauv qhov chaw muaj plua plav thiab av noo, nws yog ib qho tsim nyog yuav tsum tsis tu ncua tshem tawm cov khoom nplaum uas txuas nrog lub kiv cua kom tiv thaiv lub kiv cua kom tsis txhob hlawv vim overload.

3.2 Ua tsis tiav thiab kev tiv thaiv cov khoom siv hlau nplaum ruaj khov

Qhov tseem ceeb ntawm cov khoom siv hlau nplaum ruaj khov rau cov hlau nplaum tas mus li yog qhov tseeb ntawm nws tus kheej, thiab lawv cov nqi them rau ntau tshaj 1/4 ntawm cov khoom siv ntawm tag nrho lub cev muaj zog. Anhui Mingteng cov hlau nplaum ruaj khov lub cev muaj zog rotor cov khoom siv hlau nplaum ruaj khov siv cov khoom siv hluav taws xob zoo sib nqus thiab cov khoom siv hluav taws xob siab sintered NdFeB, thiab cov qib ib txwm muaj xws li N38SH, N38UH, N40UH, N42UH, thiab lwm yam. txhais tau tias, kom tus txheeb ze sib nqus flux tus nqi ntawm txhua qhov sib nqus hlau nyob ze, uas ua kom lub symmetry ntawm cov hlau nplaum sib nqus thiab qhov zoo ntawm cov hlau nplaum sib dhos.

Cov khoom siv hlau nplaum ruaj khov tam sim no tuaj yeem khiav mus ntev ntev nyob rau hauv qhov siab tshaj plaws qhov kub siab ntawm lub cev muaj zog winding, thiab lub ntuj demagnetization tus nqi ntawm cov hlau nplaum tsis siab tshaj 1‰. Cov khoom siv hlau nplaum tas mus li yuav tsum muaj cov txheej txheem saum npoo los tiv thaiv kev ntsuas ntsev ntsev ntau tshaj 24 teev. Rau ib puag ncig uas muaj oxidative corrosion hnyav, cov neeg siv yuav tsum tau hu rau cov chaw tsim khoom kom xaiv cov khoom siv hlau nplaum ruaj khov nrog kev tiv thaiv siab dua.

4. Yuav ua li cas xaiv lub tshuab hlau nplaum ruaj khov los hloov lub tshuab asynchronous

4.1 Txiav txim siab hom load

Cov khoom sib txawv xws li cov pob zeb, cov twj tso kua dej, thiab cov kiv cua muaj qhov sib txawv ntawm kev ua haujlwm rau cov motors, yog li cov khoom thauj khoom tseem ceeb heev rau kev tsim lossis xaiv.

4.2 Txiav txim siab lub xeev load ntawm lub cev muaj zog nyob rau hauv ib txwm ua hauj lwm

Puas yog lub cev muaj zog khiav tsis tu ncua ntawm kev thauj khoom puv lossis lub teeb? Los yog qee zaum hnyav load thiab qee zaum lub teeb load, thiab lub teeb thiab hnyav load hloov mus ntev npaum li cas?

4.3 Txheeb xyuas qhov cuam tshuam ntawm lwm lub xeev load ntawm lub cev muaj zog

Muaj ntau yam tshwj xeeb ntawm lub xeev load ntawm on-site motor. Piv txwv li, txoj siv conveyor load yuav tsum tau dais radial quab yuam, thiab lub cev muaj zog yuav tsum tau hloov ntawm pob bearings mus rau cov menyuam bearings; yog tias muaj plua plav lossis roj ntau, peb yuav tsum txhim kho qib kev tiv thaiv ntawm lub cev muaj zog.

4.4 Ambient kub

Qhov kub ntawm qhov chaw nyob ib puag ncig yog qhov peb yuav tsum tau tsom mus rau thaum lub caij xaiv lub cev muaj zog. Peb cov pa motors yog tsim los rau ambient kub ntawm 0 ~ 40 ℃ los yog qis dua, tab sis peb feem ntau ntsib cov xwm txheej uas qhov kub thiab txias ambient siab tshaj 40 ℃. Lub sijhawm no, peb yuav tsum xaiv lub cev muaj zog nrog lub zog siab dua lossis lub cev muaj zog tshwj xeeb.

4.5 On-site installation txoj kev, lub cev muaj zog installation qhov ntev

On-site installation txoj kev, lub cev muaj zog installation qhov ntev, on-site installation txoj kev thiab installation qhov ntev kuj yog cov ntaub ntawv uas yuav tsum tau, xws li cov thawj lub cev muaj zog zoo li daim duab, los yog lub installation interface qhov ntev, lub hauv paus qhov ntev thiab lub cev muaj zog tso chaw qhov chaw. Yog tias muaj kev txwv qhov chaw nyob ntawm qhov chaw, nws yuav tsum tau hloov lub tshuab cua txias txoj kev, qhov chaw ntawm lub cav hlau lead, thiab lwm yam.

4.6 Lwm yam ib puag ncig

Ntau lwm yam ib puag ncig muaj kev cuam tshuam rau kev xaiv lub cev muaj zog, xws li plua plav lossis roj paug cuam tshuam rau qib kev tiv thaiv lub cev muaj zog; Piv txwv li, nyob rau hauv marine ib puag ncig los yog ib puag ncig uas muaj pH siab, lub cev muaj zog yuav tsum tau tsim los tiv thaiv corrosion; nyob rau hauv ib puag ncig uas muaj kev vibration siab thiab qhov siab siab, muaj qhov sib txawv tsim kev xav.

4.7 Kev soj ntsuam ntawm thawj asynchronous lub cev muaj zog tsis muaj zog thiab kev ua haujlwm

(1) Nameplate cov ntaub ntawv: ntsuas voltage, ntsuas ceev, ntsuas tam sim no, ntsuas fais fab, kev ua haujlwm, qauv thiab lwm yam tsis

(2) Kev teeb tsa txoj kev: tau txais lub cev muaj zog zoo li kos duab, duab teeb tsa ntawm qhov chaw, thiab lwm yam.

(3) Kev ua haujlwm tiag tiag ntawm lub cev muaj zog: tam sim no, lub zog, lub zog hluav taws xob, kub, thiab lwm yam.

Xaus

Cov hlau nplaum tas mus li synchronous motors tshwj xeeb yog tsim rau kev siv hnyav-pib thiab lub teeb-khiav. Kev nce qib thiab siv cov hlau nplaum ruaj khov synchronous motors muaj txiaj ntsig zoo ntawm kev lag luam thiab kev sib raug zoo thiab tseem ceeb heev rau kev txuag hluav taws xob thiab txo qis emission. Nyob rau hauv cov nqe lus ntawm kev cia siab thiab stability, mus tas li hlau nplaum synchronous motors kuj muaj txiaj ntsim zoo. Kev xaiv ntawm high-efficiency mus tas li hlau nplaum synchronous motors yog ib qho kev nqis peev ib zaug nrog cov txiaj ntsig ntev.

Anhui Mingteng Permanent Magnet Electromechanical Equipment Co., Ltd. (https://www.mingtengmotor.com/) tau tsom mus rau kev tshawb fawb, kev tsim kho, tsim khoom thiab muag khoom ntawm ultra-high-efficiency mus tas li magnet synchronous motors rau 17 xyoo. Nws cov khoom lag luam npog tag nrho cov high-voltage, low-voltage, tas li zaus, hloov pauv zaus, cov pa, tawg-pov thawj, tsav ncaj qha, hluav taws xob rollers, thiab tag nrho-hauv-ib tshuab, aiming kom muaj zog tsav tsheb ntau dua rau cov khoom siv.

Anhui Mingteng cov hlau nplaum ruaj khov motors muaj tib qhov kev teeb tsa sab nraud raws li qhov tam sim no dav siv asynchronous motors, thiab tuaj yeem hloov pauv asynchronous motors. Tsis tas li ntawd, muaj ib pab kws tshaj lij los tsim thiab muab cov neeg siv khoom nrog kev hloov pauv dawb. Yog tias koj xav tau kev hloov pauv asynchronous motors, thov tsis txhob yig tiv tauj peb, thiab peb yuav pab koj tag nrho lub siab dawb paug!

Post lub sij hawm: Aug-23-2024